The machines must be calibrated every year with certifications available.

Button pull test machine calibration.

Button pull test machine calibration needle detector machine calibration textile moisture meter calibration.

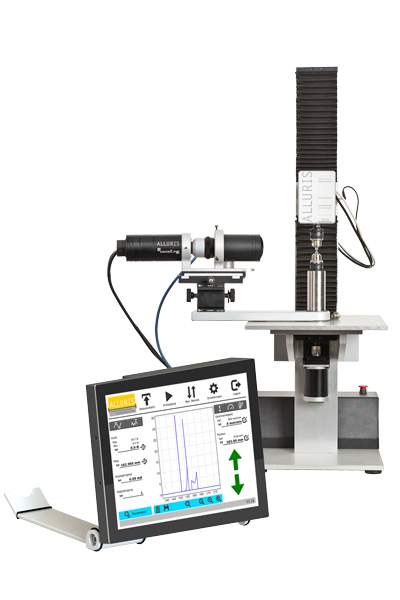

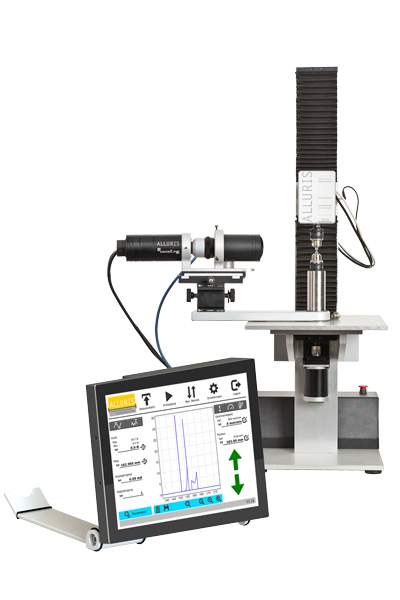

Button snap pull testing button snap pull tester i2 button snap pull tester i2 to determine the pulling strength of any type of button and snaps used in garments with maximum capacity 30 kg least count 250 gm.

Button pull test machine calibration.

The sop of the button pull testing must be displayed near the machine.

Depending on the type of the test the manufacturer s specifications and the international standard used the pull test can be separated into two categories.

Button snap tester machine the button snap tester to determine the holding or breaking strength of prong ring attached snap fasteners onto garments.

It is also used to determine the holding or breaking strength of prong ring attached snap fasteners onto garments to ensure the button.

Pull testing to the minimum tensile value.

Pull testing is actually a means of evaluating the mechanical properties of the crimped connections.

Button pull test sop for apparel industry button pulls test is used to determine the pulling strength of any type of button and snaps used in garments.

A specific template uses to calibrate the machine to find out the accuracy of a machine by pulling that into a machine of known weight.

All factories must have a pull test machine.

Need to calibrate machine at least once in a week by supplier m c calibrating tools.

4 different types of jaws with calibration weight all accessories as per american gap european h m standards.

Button pull test machine calibration.

The snap component is gripped by the upper snap clamp and the garment is fixed to the lower fabric clamp.

China button snap pull strength test machine find details about china button snap pull tester button pull test machine from button snap pull strength test machine gester instruments co ltd.

A sticker with date of calibration and expiry date must be displayed on the machine.

Consists of an upper snap clamp a lower fabric clamp force gauge mounted on a stand.

Aim at providing the strict reference basis for garments manufacturers to ensure the snaps buttons and fixed accessories can be fixed on garments properly so as to prevent from snap button fall off and swallow risks for infants.

Calibration certificate should be displayed near the machine.

Button pull test sop.